Mechanical Stability and Flow Analysis of Hollow Microneedle array for Transdermal Drug Delivery

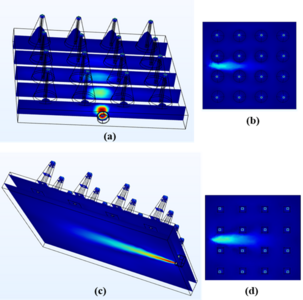

Transdermal drug delivery is an emerging mechanism for continuous systematic solutions in medical healthcare problem. Transdermal drug delivery has significant advantages when compared to conventional methods such as oral administration or intramuscular injection. Most of the conventional methods has some drawbacks such as high cost, complexity and user difficulties. The most effective recent technology for transdermal drug delivery is through microneedle array. Microneedle-based transdermal drug delivery into the skin has gained attraction for the past few years. Microneedles are minimally invasive devices that permit transdermal drug delivery by making tiny pores through the skin. Transdermal Drug Delivery through hollow microneedle arrays with painless insertion and controlled flow rate is a challenging task. An analysis of optimum microneedle geometry parameters for successful penetration is always required before microneedle production. The detailed microneedle stability and flow rate analysis is investigated by COMSOL Multiphysics tool. In this work, a novel hollow microneedle array with integrated reservoir and cylindrical center lumen is designed for transdermal drug delivery (TDD) applications. Two different geometry structures such as conical and pyramidal microneedle were taken into consideration for the drug delivery. A detailed analysis of geometry optimization is performed with the specification of microneedle height (400–1000 μm), base diameter (150–300 μm), tip diameter (10–30 μm) and center-to-center spacing of 650 µm. The microneedle array is made with PVA material and comprises of 16 microneedles arranged in 4x4 matrix. With the use of solid mechanics module, a stress analysis is conducted on 4x4 conical and pyramidal microneedle array under axial and bending loading conditions. The impact of modification of microneedle geometry with respect to mechanical stability was examined. An in-depth flow analysis is performed with laminar flow module, in which water and glucose were used as the fluids for the microfluidic study. It has been discovered that sharper conical tip has greater mechanical stability with less bending and a higher flow rate of 320 µL/min compared to a pyramidal microneedle array, which has a flow rate of 230 µL/min. The skin insertion finite element analysis of 4x4 PVA microneedle array is performed with three layer skin model and the endurance of the microneedle array is examined by applying a buckling load to the microneedle base which results in less stress and bending.

Download

- Gwthami_6821_Paper.pdf - 0.65MB

- Gowthami_6821_Poster.pptx - 3.21MB